SERVICES

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

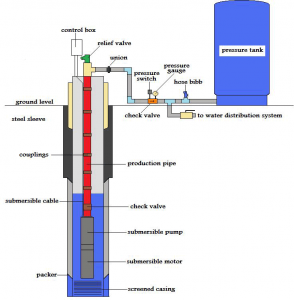

The basic (Standard Pressure) residential water well system is a system that has been proven over many generations.

The submersible pump pushes water up through the drop pipe to the surface. There is a check valve installed every 200’ that keeps the water from flowing back into the well. The pressure switch turns the pump on when the pressure drops and off when the pressure builds up again. This typically happens over a 20PSI range.

The pressure is then stored in an above-ground pressure tank. If the system builds up too much pressure, the pressure relief valve will release the excess pressure to prevent the submersible pump or PVC drop pipe from being damaged. Below is a basic diagram of this setup.

This is a system that can be installed on almost any water well, it has been tested for many years and works great. However, that doesn’t mean that the system doesn’t have its drawbacks. One of the main flaws to a Standard Pressure System is that the submersible pump turns on and off as the pressure in the pressure tank rises and falls every 20PSI.

During high water usage times, such as showers or lawn irrigation this results in a high number of pump starts and stops. These hard starts/stops is what shortens the lifespan of your downhole pump. Submersible pumps are rated for 20,000 starts and stops so the more we can minimize the pump kicking on and off the greater the lifespan of your pump.

This can be problematic for those customers who are looking to use their water well for lawn irrigation. Most sprinkler systems require a solid 60PSI to efficiently water the yard, so the 20PSI pressure range can be frustrating or even problematic since the sprinklers will throw farther/shorter as the pressure rises/falls. This could result in dry/brown spots in your lawn.

A solution for these problems can be a Constant Pressure System that operates off of a variable speed drive.

Did you know that you can have city-like water pressure on your own private water well?

Constant Pressure Water Systems is relatively new to the water well industry but is a great option for those who are wanting to run their private water well to provide water to their entire household, sprinkler systems, shops, swimming pools, etc.

A Constant Pressure System is ran by a variable frequency drive (VFD), which allows the motor speed to change as flow demand changes. The pump controller converts single phase 230 volt power to three phase 230 volt power. By converting the power, the VFD is able to control the speed of the pump allowing the pump to turn at the speed necessary to provide constant pressure. Also by converting single phase power to three phase power it costs a third less to run the Constant Pressure pump versus the Standard Pressure pumps.

A typical submersible Constant Pressure pump pushes water up through the drop pipe to the surface. Check valves are installed every 200’ to keep water from flowing back into the well. When the pressure in the system drops by 5PSI, a pressure sensor tells the pump controller to turn the pump on. Then, as described above, the controller varies the speed of the pump to maintain the pressure within 2PSI of your desired setting (under most conditions). The pressure is stored in a small pressure tank— typically 20 gallons (compared to the larger 90 gallon tank for Standard Pressure systems).

The pump controller is programmed to recognize a variety of conditions that might damage the pump and temporarily shut off the pump if those situations arise. Should the pump controller fail to monitor the pressure and the system builds up too much pressure, the pressure relief valve will release the excess pressure to keep from damaging the submersible pump & drop pipe.

Another advantage to the Constant Pressure System is that as long as there is at least 1GPM water demand, your pump stays on. This eliminates the hard start/stop issue that the Standard Pressure Systems have, and can extend the lifespan of your pump. The Constant Pressure System also turns on very gradually when it does turn off or on. This too can lengthen the life of your pump.

The Constant Pressure System is great for those homeowners who want the assurance of full pressure throughout their entire household, no matter how many faucets, hose bibs, or sprinklers are running at the same time. This system also has a much smaller footprint in your yard and everything (including the well head) is easily hidden with a landscape rock or camouflaged by your surrounding landscape.

A photovoltaic solar powered pump system has three parts:

–solar panels

–the controller

–the pump

The solar panels make up most (up to 80%) of the systems cost. The size of the PV-system is directly dependent on the size of the pump, the amount of water that is required (m³/d) and the solar irradiance available.

The purpose of the controller is twofold. Firstly, it matches the output power that the pump receives with the input power available from the solar panels. Secondly, a controller usually provides a low voltage protection, whereby the system is switched off, if the voltage is too low or too high for the operating voltage range of the pump. This increases the lifetime of the pump thus reducing the need for maintenance. Other ancillary functions include automatically shutting down the system when water source level is low or when the storage tank is full, regulating water output pressure, blending power input between the solar panels and an alternate power source such as the grid or a petrol generator, and remotely monitoring and managing the system through an online portal offered as a cloud service by the manufacturer.

Voltage of the solar pump motors can be AC (alternating current) or DC (direct current). Direct current motors are used for small to medium applications up to about 4 kW rating, and are suitable for applications such as garden fountains, landscaping, drinking water for livestock, or small irrigation projects. Since DC systems tend to have overall higher efficiency levels than AC pumps of a similar size, the costs are reduced as smaller solar panels can be used.

Finally, if an alternating current solar pump is used, an inverter is necessary that changes the direct current from the solar panels into alternating current for the pump. The supported power range of inverters extends from 0.15 to 55 kW and can be used for larger irrigation systems. However, the panel and inverters must be sized accordingly to accommodate the inrush characteristic of an AC motor. To aid in proper sizing, leading manufacturers provide proprietary sizing software tested by third party certifying companies. The sizing software may include the projected monthly water output which varies due to seasonal change in insolation.

Solar powered water pumps can deliver drinking water as well as water for livestock or irrigation purposes. Solar water pumps may be especially useful in small scale or community based irrigation, as large scale irrigation requires large volumes of water that in turn require a large solar PV array.As the water may only be required during some parts of the year, a large PV array would provide excess energy that is not necessarily required, thus making the system inefficient.

A water tank is a container for storing water. Water tanks are used to provide storage of water for use in many applications, drinking water, irrigation agriculture, fire suppression, agricultural farming, both for plants and livestock, chemical manufacturing, food preparation as well as many other uses. Water tank parameters include the general design of the tank, and choice of construction materials, linings. Various materials are used for making a water tank: plastics (polyethylene, polypropylene), fiberglass, concrete, stone, steel (welded or bolted, carbon, or stainless).

Improved quality of water

— By allowing the water to settle, any solids in the water will drop to the bottom of the tank.

— As the water is pumped into the storage tank it allows air to mix into the water. When this happens, a chemical reaction occurs and oxidizes any iron particles that are in the water. The iron particles turn into a solid and then drop out of the water.

— Well water tends to have a lot of dissolved sulfur gas in it that will give your water a “rotten egg” smell. A storage tank allows that gas to be vented out of the water, instead of being pumped into your home.

Improved longevity of downhole equipment

— Starts and stops are very hard on your submersible pump and motor. By installing a storage tank the downhole equipment will start and stop 75% less than the conventional setup. In theory, this system should double or even triple the life of an average pump.

Ability to install a smaller horsepower submersible pump and motor

— Since you are pumping water into a zero pressure storage tank, you are able to go with a smaller horsepower pump in the well. Smaller pumps are cheaper to replace and generally last longer.

A water filter removes impurities by lowering contamination of water using a fine physical barrier, a chemical process, or a biological process. Filters cleanse water to different extents for purposes such as providing agricultural irrigation, accessible drinking water, public and private aquariums, and the safe use of ponds and swimming pools.

Filters use sieving, adsorption, ion exchanges and other processes to remove unwanted substances from water. Unlike a sieve or screen, a filter can potentially remove particles much smaller than the holes through which its water passes.

From installations to repairs, we can help you with all your well pump needs. Depending on the type of pump, some well pumps simply deliver water from the well to a pressure tank, while others will pressurize the entire water system. Dialing in the specific well type and capacity is a critical step in getting the most use out of your well. Our experts can help you size the right pump for a new well or assess your current pump if it is not meeting your needs. We’ll also fix water line leaks and troubleshoot problems if needed.

Routine inspection of a water well system can help ensure it is operating properly,

prolong its useful life, and protect your investment. Most importantly, inspections

can protect your health by discovering issues that could result in water quality

problems presenting a health risk.

Wells should be evaluated annually by a licensed or certified water well systems

professional. In between annual inspections, well owners should look for signs that a

professional should be called sooner.